Scientists develop innovative and sustainable lubrication system to improve wear and corrosion resistance in mechanical applications

The research findings provide a viable alternative to environmentally harmful lubricant additives and pave the way for further advances in sustainable lubrication technologies.

A team of researchers from the Faculty of Sciences and Technology of the University of Coimbra (FCTUC) has developed an innovative and sustainable lubrication system that significantly improves wear and corrosion resistance in mechanical applications.

Fábio Ferreira, a researcher at the Department of Mechanical Engineering (DEM) at FCTUC and the Centre for Mechanical Engineering, Materials and Processes (CEMMPRE), led the development of this new system as part of the international project LubEnergy.

"This research was driven by the need to improve mechanical components as friction and wear are becoming increasingly problematic, leading to higher energy consumption. For example, in a car, if the engine experiences significant friction, it requires more fuel to move its components and power the vehicle," explains Fábio Ferreira.

He adds: "By integrating gadolinium-doped diamond-like carbon (Gd-DLC) coatings with ionic liquids, we not only improve the performance of these components by almost 50%, but also address the environmental concerns associated with conventional lubricant additives such as Zinc dialkyldithiophosphates (ZnDTPs).

"Traditional lubricants rely on additives that can have a negative environmental impact due to their high levels of phosphorus, sulphur, and zinc," the researcher notes, emphasising that "the aim was to develop a more sustainable alternative without compromising performance".

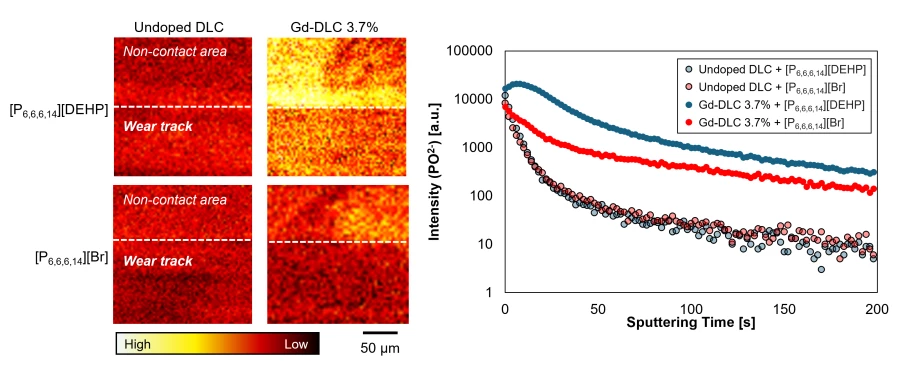

The research involved developing DLC coatings with varying concentrations of gadolinium to improve their wear-resistance properties. When combined with specific ionic liquids, the Gd-DLC coatings not only reduced wear, but they also provided excellent corrosion protection, even in the presence of bromide-containing ionic liquids, which typically corrode steel surfaces.

According to Fábio Ferreira, surface analysis techniques revealed that gadolinium facilitates the adsorption of phosphate ions from ionic liquids onto the DLC surface, resulting in the formation of phosphorus-rich tribofilms that enhance wear resistance.

"These findings offer a viable alternative to environmentally harmful lubricant additives and pave the way for further advances in sustainable lubrication technologies," the researcher concludes, adding that "the research developed has significant implications for various industries seeking to improve mechanical performance while reducing environmental impact."